JBT Completes Bevcorp Acquisition

CHICAGO, September 1, 2022 /PRNewswire/ — JBT Corporation (NYSE: JBT), a global technology solutions provider to high-value segments of the food and beverage industry, announced today it has completed the previously announced acquisition of Bevcorp.

“We are excited to announce that we completed the acquisition of Bevcorp,” said Brian Deck, President and Chief Executive Officer. “The acquisition of Bevcorp expands JBT’s capabilities in the carbonated beverage processing and packaging market, and it brings a highly resilient business model with more than 60 percent recurring revenue along with a best-in-class service culture. The unique combination of Bevcorp and JBT allows for meaningful cross selling and future growth opportunities in both food and beverage.”

Bevcorp Overview

Bevcorp is a leading provider of equipment and aftermarket support for the beverage processing and packaging market in the United States. The business provides core technology solutions in blending, handling, filling, and closing to a range of diverse customers, including blue chip companies. Bevcorp’s product offerings are used in high-value segments of the beverage market, including carbonated soft drinks, seltzers, carbonated water, energy drinks, and ready-to-drink alcoholic blends. Additionally, the business’ unique process know-how and service culture provide a resilient mix of rebuilds, aftermarket parts, and services.

“By integrating Bevcorp into the JBT family of brands and leveraging our global sales and service network, we can expand Bevcorp’s growth opportunities beyond the United States,” added Deck. “Additionally, JBT’s existing strength in non-carbonated beverage and food processing creates cross selling synergies with Bevcorp.”

JBT acquired Bevcorp for an enterprise value of $290 million, subject to customary post-closing adjustments. The transaction was treated as a purchase of assets, which provides a meaningful tax step-up benefit with a net present value of approximately $35 million.

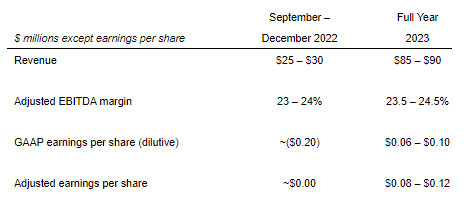

Bevcorp Guidance

The table below reflects guidance specific to Bevcorp and is relative to the Company’s prior guidance. 2022 Bevcorp adjusted EBITDA margin and adjusted earnings per share exclude the estimated impact of transaction costs, inventory step-up, and non-recurring integration costs. These costs are expected to be approximately $9 million. Bevcorp is not expected to have a meaningful impact on the Company’s adjusted earnings per share in 2022.

JBT Net Leverage Ratio

JBT utilized its existing credit facility to fund the purchase price of Bevcorp. The Company’s third quarter 2022 net leverage ratio is expected to temporarily exceed its target of 2.0 – 3.0x, and JBT expects that its net leverage ratio will be below 3.0x by year end 2022.

JBT Corporation (NYSE: JBT) is a leading global technology solutions provider to high-value segments of the food & beverage industry with focus on proteins, liquid foods and automated system solutions. JBT designs, produces and services sophisticated products and systems for multi-national and regional customers through its FoodTech segment. JBT also sells critical equipment and services to domestic and international air transportation customers through its AeroTech segment. JBT Corporation employs approximately 7,000 people worldwide and operates sales, service, manufacturing and sourcing operations in more than 25 countries.

This release contains forward-looking statements as defined in the Private Securities Litigation Reform Act of 1995. Forward-looking statements are information of a non-historical nature and are subject to risks and uncertainties that are beyond JBT’s ability to control. Forward-looking statements include, among others, statements relating to the expected impact of the COVID-19 pandemic on our business and our results of operations, our plans to mitigate the impact of the pandemic, our strategic plans, our restructuring plans and expected cost savings from those plans, our liquidity and our covenant compliance. The factors that could cause our actual results to differ materially from expectations include but are not limited to the following factors: the duration of the COVID-19 pandemic and the effects of the pandemic on our ability to operate our business and facilities, on our customers, on our workforce resulting in higher labor absenteeism, on our supply chains due to extended delivery times and unavailability of required components and freight, on our cost of labor due to higher labor turnover and shortage of skilled labor and on the economy generally; fluctuations in our financial results; unanticipated delays or acceleration in our sales cycles; deterioration of economic conditions; disruptions in the political, regulatory, economic and social conditions of the countries in which we conduct business; changes to trade regulation, quotas, duties or tariffs; risks associated with acquisitions or strategic investments; fluctuations in currency exchange rates; increases in energy or raw material prices, freight costs, and inflationary pressures; changes in food consumption patterns; impacts of pandemic illnesses, food borne illnesses and diseases to various agricultural products; weather conditions and natural disasters; impact of climate change and environmental protection initiatives; our ability to comply with the laws and regulations governing our U.S. government contracts; acts of terrorism or war, including the recent conflict between Russia and Ukraine; termination or loss of major customer contracts and risks associated with fixed-price contracts, particularly during periods of high inflation; customer sourcing initiatives; competition and innovation in our industries; difficulty in implementing our business strategies, including the timing of our previously announced review of strategic alternatives for the AeroTech platform, our ability to identify or develop any strategic alternatives, execute on material aspects of such strategic alternatives, and whether we can achieve the potential benefits of such strategic alternatives. our ability to develop and introduce new or enhanced products and services and keep pace with technological developments; difficulty in developing, preserving and protecting our intellectual property or defending claims of infringement; catastrophic loss at any of our facilities and business continuity of our information systems; cyber-security risks such as network intrusion or ransomware schemes; loss of key management and other personnel; potential liability arising out of the installation or use of our systems; our ability to comply with U.S. and international laws governing our operations and industries; increases in tax liabilities; work stoppages; fluctuations in interest rates and returns on pension assets; availability of and access to financial and other resources; and other factors described under the captions “Risk Factors” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations” in the Company’s most recent Annual Report on Form 10-K filed by JBT with the Securities and Exchange Commission and in any subsequently filed Form 10-Q. In addition, many of our risks and uncertainties are currently amplified by and will continue to be amplified by the COVID-19 pandemic. Given the highly fluid nature of the COVID-19 pandemic, it is not possible to predict all such risks and uncertainties. JBT cautions shareholders and prospective investors that actual results may differ materially from those indicated by the forward-looking statements. JBT undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future developments, subsequent events or changes in circumstances or otherwise.

Investors & Media: Media: Kedric Meredith +1 312 861 6034

To view the original version on PR Newswire, please click here.

high-speed fillers, blenders and container handling equipment for the beverage industry, announces its acquisition of East Coast Seamers, a supplier of rebuilt Angelus, Continental and Canco can seamers and seamer service provider. This acquisition strengthens Bevcorp’s commitment to the beverage equipment marketplace, providing increased services to domestic and worldwide customers by expanding resources and capabilities in seamer rebuilding and service.

high-speed fillers, blenders and container handling equipment for the beverage industry, announces its acquisition of East Coast Seamers, a supplier of rebuilt Angelus, Continental and Canco can seamers and seamer service provider. This acquisition strengthens Bevcorp’s commitment to the beverage equipment marketplace, providing increased services to domestic and worldwide customers by expanding resources and capabilities in seamer rebuilding and service.

As for other design changes technology now enables, Hendrickson cites what was done with a bowl used in the filling process. The product within it has to be maintained at a certain level, with more periodically added in a foam-free fashion. Previously, a product change or adjustment required stopping a machine, opening up guarding, making a mechanical adjustment, closing up the machine and starting it up again—a time-consuming sequence that might have to be repeated. Now, an electronic level control system that sits inside the guarding and communicates wirelessly enables adjustments to be made without stopping the machine at all.

As for other design changes technology now enables, Hendrickson cites what was done with a bowl used in the filling process. The product within it has to be maintained at a certain level, with more periodically added in a foam-free fashion. Previously, a product change or adjustment required stopping a machine, opening up guarding, making a mechanical adjustment, closing up the machine and starting it up again—a time-consuming sequence that might have to be repeated. Now, an electronic level control system that sits inside the guarding and communicates wirelessly enables adjustments to be made without stopping the machine at all.